Chain Efficiency Test Protocol : Endurance

Following the acquisition of Friction Facts back in November 2016, CeramicSpeed are now positioned to test and validate the majority of industry claims when it comes to chain efficiency and frictional savings.

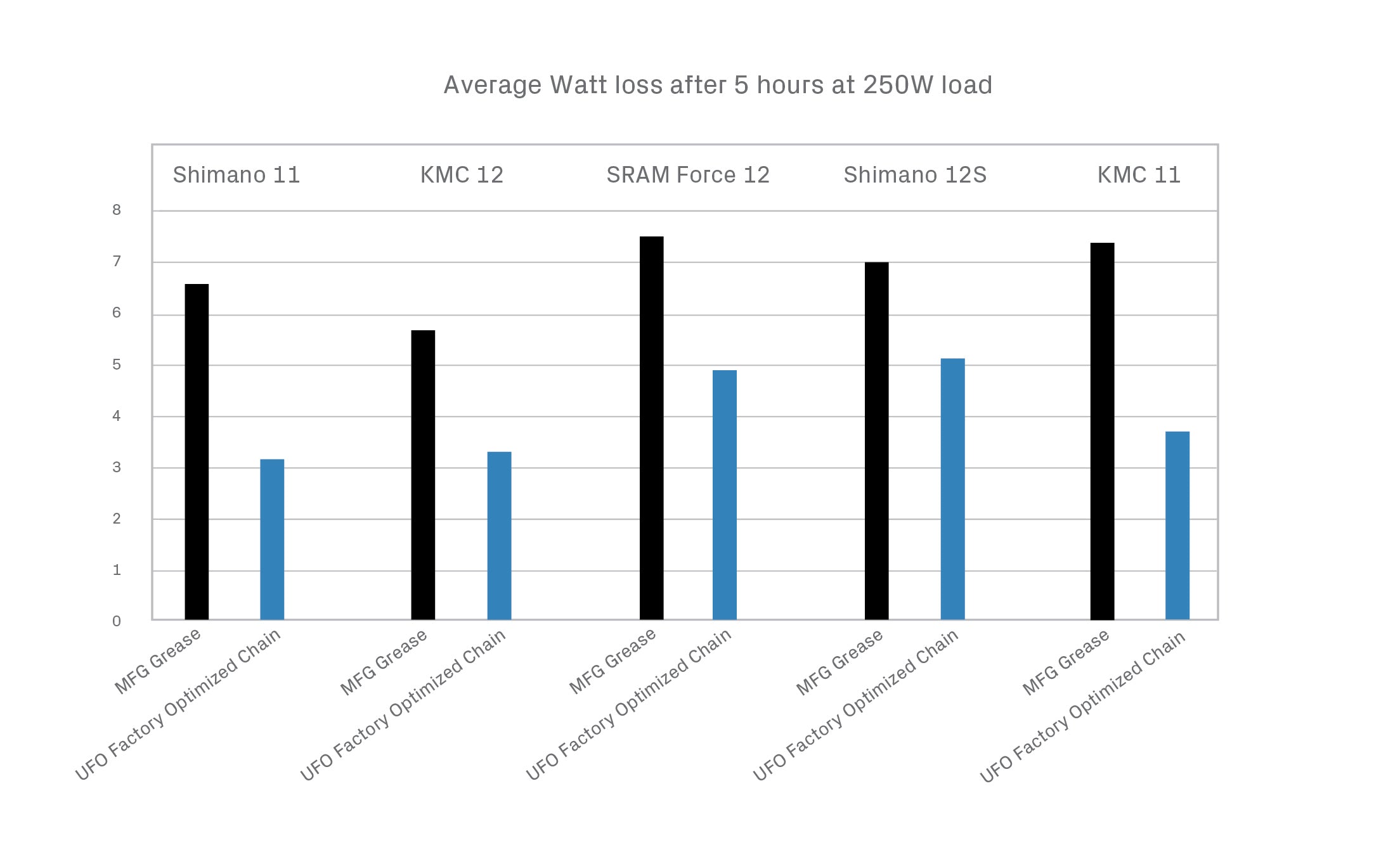

The test results above showcase the performance of CeramicSpeed UFO Racing Chains against other treated chain products. The testing was performed on the Endurance Machine in combination with the Full Tension Tester. The results showcase the CeramicSpeed UFO Racing Chain to be the fastest chain – also over time – supported by a thorough testing protocol. Our data shows consistent/stable performance for min. 600km

Goal

The goal of the ”Chain Efficiency Test Protocol: Endurance” is to analyze the frictional losses of a chain over a given timeframe or distance, in clean lab conditions.

Background

Friction Facts, CeramicSpeed's dedicated drivetrain testing laboratory, has performed numerous Chain Efficiency tests of drip lubricants and factory-optimised chains.

While these specific tests are very valuable to determine initial frictional loss levels, they do not provide any indicator of how the chain lubricant (or coating, or optimization) will perform from a longevity standpoint. With this in mind, the Chain Efficiency Endurance Test provides data on both the initial frictional loss values, plus the loss values of the lubricant over time/distance.

It must be noted that this Endurance Test is performed in the laboratory in clean conditions. It is acknowledged that this test might not be representative of actual outdoor conditions. Yet, by not including the variable of contaminants, the test analyzes the true nature of a lubricant and its chemical backbone to withstand the mechanical stresses of a fully loaded drivetrain over time.

Friction Facts does perform chain lubricant contamination tests in-lab, and on the road, which are separate and different test protocols.

The Chain Efficiency Endurance Test Protocol

Preparation

Typically, a single chain is used for this test.

If a factory-treated chain, such as a UFO Racing Chain, that is pre-treated with an optimisation treatment from the factory, is the subject of the test, the manufacturer’s initial break-in instructions are followed, if applicable.

If a drip lubricant is the subject of the test, a pristine, yet well broken-in chain is used. Breaking-in a chain prior to testing removes the variable of the chain’s decreasing friction due to self-polishing during break-in, which would influence the results of the lubricant's effectiveness. The drip lubricant is applied to the cleaned chain per the manufacturer’s instructions. Also, any additional processes are followed as per the instructions, such as dry time, wipe down, layering, etc. It should be noted that Friction Facts uses a 3-step solvent ultrasonic cleaning process to ensure the test chain is completely stripped prior to lubricant application.

Testing

The chain is placed on the High-Precision Chain Efficiency Tester and loaded accordingly to simulate 250W of rider output. Additional details of the Chain Efficiency Tester set up.

The zero’d Tester is turned on and set at 95RPM cadence.

The tester is allowed to run for approximately 5 minutes, or until the chain friction has stabilized. Some lubricants/optimisations require a longer stabilization period, upwards of 15-20 minutes.

After stabilization, the data point is captured and documented.

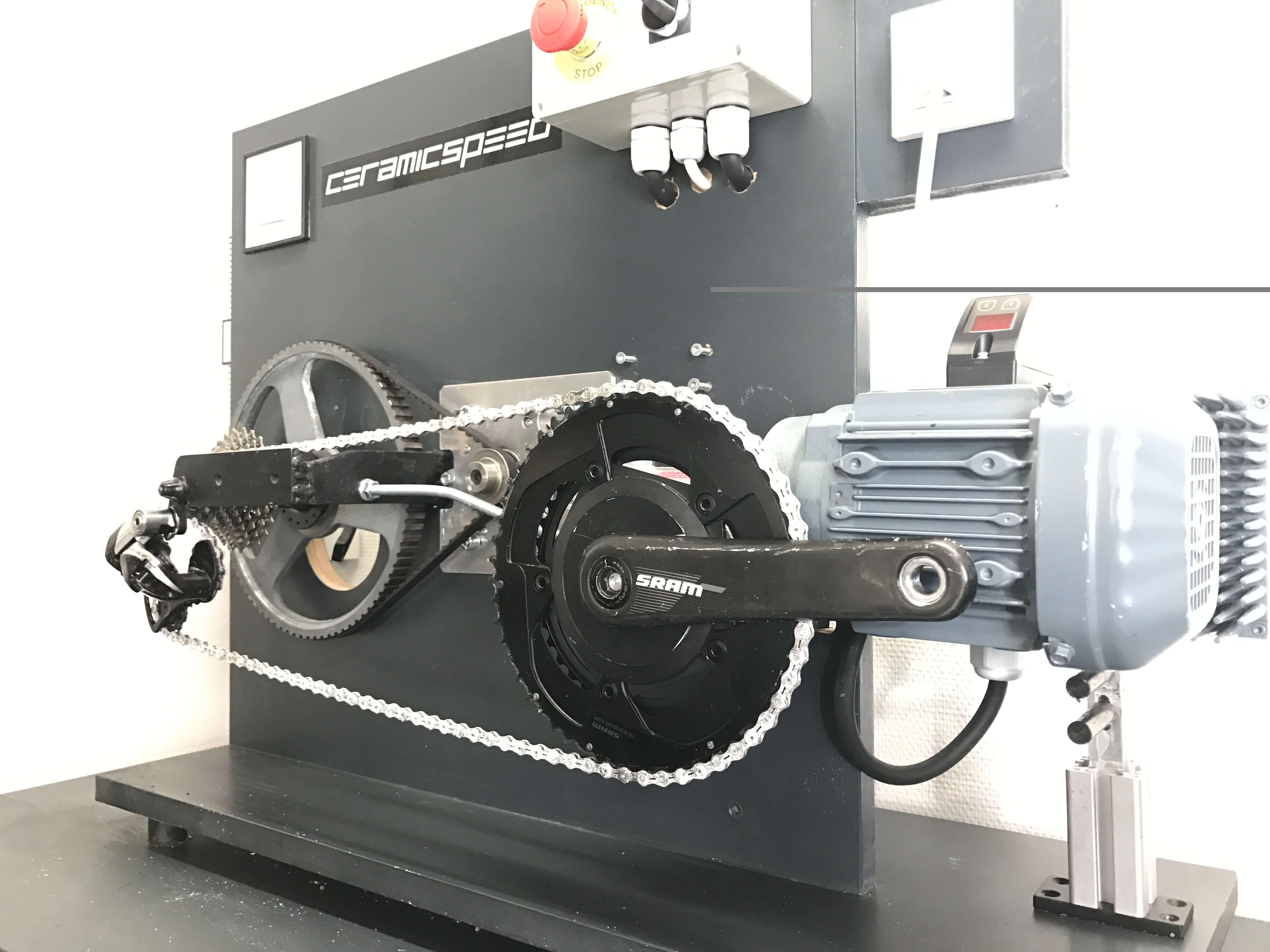

The chain is then moved to the Endurance Machine. This machine differs from the Chain Efficiency Tester in that it is designed to represent an actual bicycle drivetrain, and does not provide friction measurements. The Endurance Machine simply puts the chain through the rigors of an actual drivetrain at a given load and RPM, including cross-chaining and different rear derailleur setups, if applicable to the specific test. The Endurance Machine is typically set at 250W output and 95RPM.

The chain is run on the Endurance Tester for a given amount of time. Typically, 30-minute intervals are used.

After being run on the Endurance Tester, the chain is removed and placed on the Chain Efficiency Tester for one minute, for the high-precision friction measurement.

The process is repeated; the chain runs on the Endurance Tester for 30 minutes, then friction is measured by the Chain Efficiency Tester until the desired total test duration is achieved.

For example, in a 4-hour endurance test, the process will be repeated 8 times, providing 9 friction data points over the 4 hours.

The data is typically plotted on a graph with Friction vs duration axes.